|

PECHINEY MARINE SEALIUM ALLOY

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Created and patented by Pechiney Marine, Sealium 5383 optimises the overall productivity of shipbuilders and the performance of vessels in general as it makes them more robust, safer, and user-friendly. In just a few years, Sealium has become the international industry reference for fast ferries.

Applications

Sealium may be used wherever a stronger welded aluminum structure is desired, from hulls to superstructures. Marine structures benefit from the excellent corrosion resistance offered by Sealium . Smaller boats (< 50m) benefit from improved scantlings, which translate into structural weight savings on patrol craft, increased strength on work boats or added interior space in luxury yachts. Larger vessels (> 50m) profit from the increased strength and improved fatigue behavior of Sealium . Cruise ship superstructures can be lightened further while improving stability and not compromising strength or corrosion resistance.

Advantages

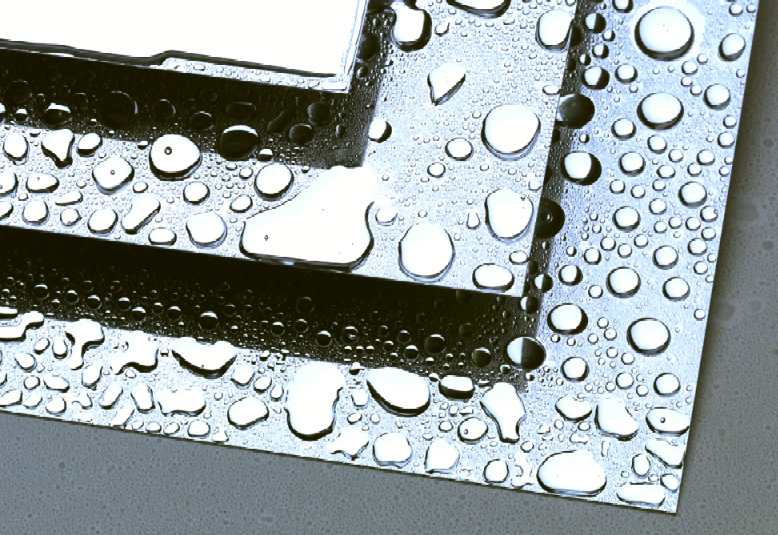

Corrosion Resistance

Marine grade Sealium is tested as per ASTM B209, and therefore capable of exhibiting no evidence of exfoliation corrosion. Intergranular corrosion (IGC) and stress corrosion (SCC) tests (Interacid test and ASTM G44) as well as ASSET tests (ASTM G66) on base and welded metal samples of Sealium show significantly better corrosion resistance than standard 5083-H116. Accelerated (artificial ageing for 7 days at 100¡C) and natural exposure (marine atmosphere and immersion) as well as experience have proven the long term corrosion resistance of Sealium to be markedly improved over that of 5083-H116.

Type Approval

Sealium 5383 Sheets/Plates have been approved by the major classification societies :

Other Alloys Available: 5083 5086 5754 6005a 6061 6082

Production H116 and H321 tempers are ASSET tested as per ASTM G66 / ASTM B209, and therefore capable of exhibiting no evidence of exfoliation corrosion. Intergranular corrosion (IGC) and stress corrosion (SCC) tests (Interacid test and ASTM G44) as well as ASSET tests on base and welded metal samples of 5383 show significantly better corrosion resistance than standard 5083. Accelerated (artificial ageing for 7 days at 100°C), natural exposure (marine atmosphere and immersion) and experience have proven the long term corrosion resistance of 5383 to be markedly improved over that of 5083.

CONSTELLIUM

INNOVATION

CONTACTS

Constellium Headquarters http://www.constellium.com/aluminium-company

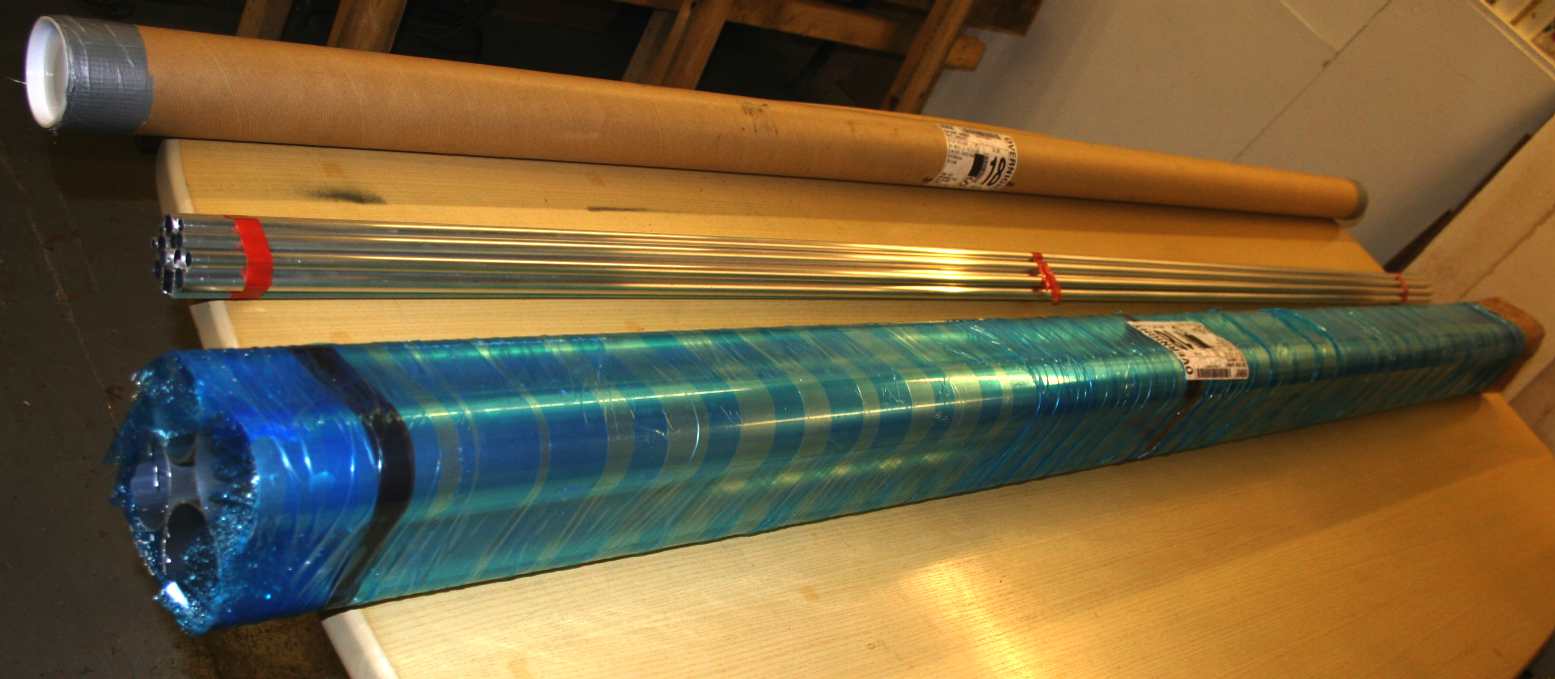

Transporting a coil of sealium aluminum

Pechiney Wins Three Aluminum Deals

LONDON, July 24, 2002 (Reuters) - French aluminium producer Pechiney said on Wednesday it would provide environmentally friendly metal production technology for three of the world's major expansion projects.

The company, which is the world's sixth largest aluminium producer, said in a statement that in the last quarter, it had won contracts to supply its new AP30 potline technology to aluminium expansions in the Middle East, South Africa and Quebec.

Pechiney will provide its services to Aluminium Bahrain, which is adding 308,000 tonnes to its existing capacity of 500,000 tonnes a year and BHP Billiton's 132,000-tonne expansion at its Hillside smelter in South Africa.

The third project is the 302,000-tonne expansion at the Aluminerie Alouette Inc smelter in Canada, which belongs to a consortium that includes Alcan Inc (20 percent), Austria Metall (20 percent), and Norsk Hydro (20 percent) among others.

"Over 80% of new aluminium smelting facilities commissioned worldwide in recent years use Pechiney technology," said Jean-Dominique Senard, senior executive vice president Pechiney Aluminum Metal.

Pechiney's AP30 cells help to cut harmful emissions fromn the aluminium production process.

The company also competes with other major world aluminium producer such as world number one Alcoa Inc or Norsk Hydro of Norway to supply its cell technology to green and brownfield projects.

Pechiney, which supplies three percent of the world's 27 million tonnes of aluminium, said it was also supplying AP30 technology to BHP Billiton's expansion of its Mozal smelter in Mozambique, which is increasing to some 500,000 tonnes from 250,000 tonnes at present and is one of the most efficient smelters in the world.

The company added that it will overhaul an anode baking furnace for Norsk Hydro's recently acquired 150,000-tonne Kurri Kurri smelter in Australia.

French aluminum group Pechiney wrapped up a US$208 million deal to expand Venezuela's state-owned bauxite and alumina producer Bauxilum - Investments and M&AsLatin CEO: Executive Strategies for the Americas, May, 2001

French aluminum group Pechiney wrapped up a US$208 million deal to expand Venezuela's state-owned bauxite and alumina producer Bauxilum. Pechiney plans to spend US$108 million to expand production capacity to 2 million tons within three years, up from the current 1.7 million tons. The deal stems from an agreement last December with state holding companies Corporacion Venezolana de Guyana (CVG) and Corporacion Aluminios de Venezuela (CAV).

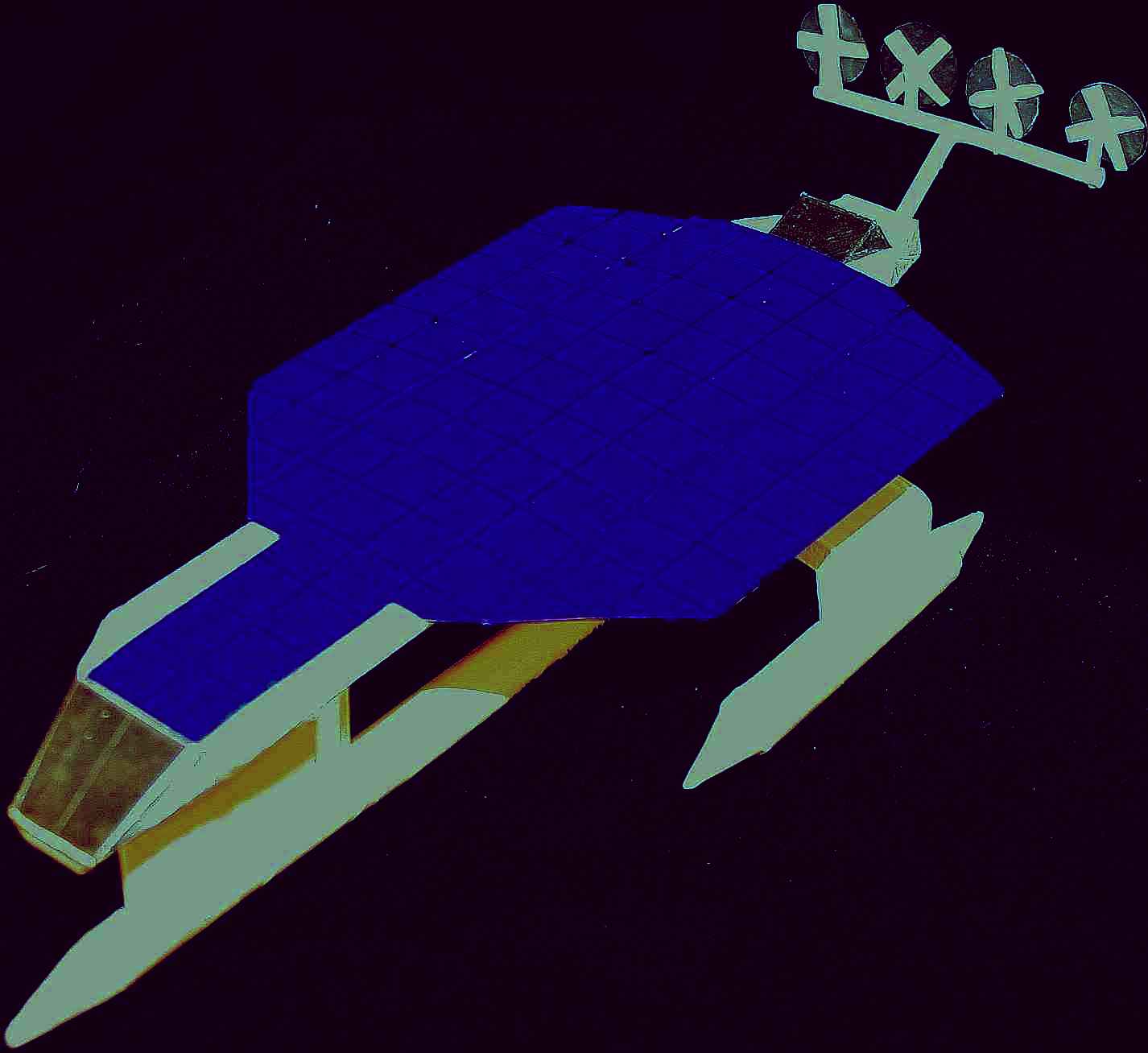

Self cleaning solar alloy

Solarnavigator is an Autonomous robot ship with an extremely efficient active hull made of marine grade aluminum. This ship is ideal as an oceanographic survey vessel due to its endurance capabilities, relatively high speed and low operating costs.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This website is copyright © 1991- 2013 Electrick Publications. All rights reserved. The bird logo and names Solar Navigator and Blueplanet Ecostar are trademarks ™. The Blueplanet vehicle configuration is registered ®. All other trademarks hereby acknowledged and please note that this project should not be confused with the Australian: 'World Solar Challenge'™which is a superb road vehicle endurance race from Darwin to Adelaide. Max Energy Limited is an educational charity working hard to promote world peace.

|