|

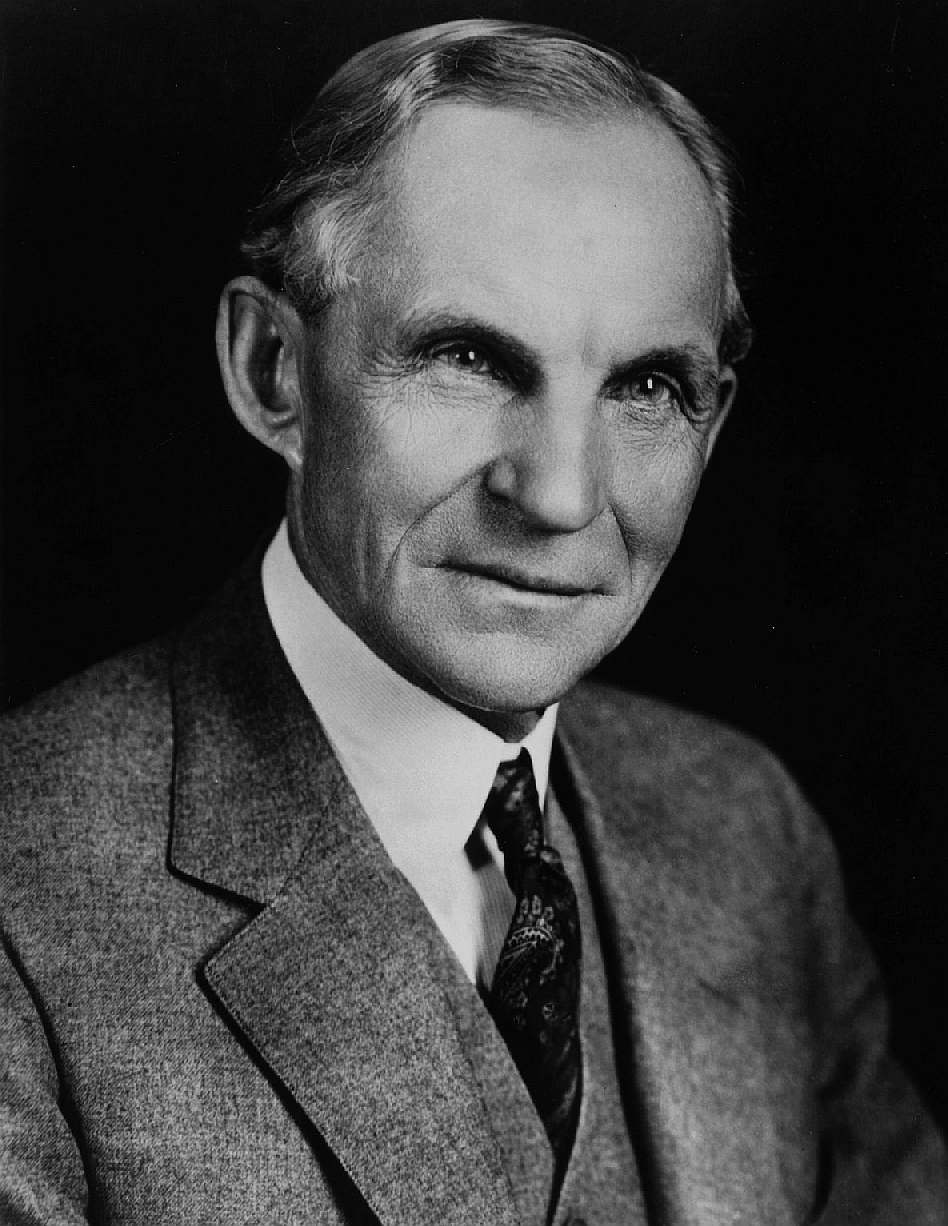

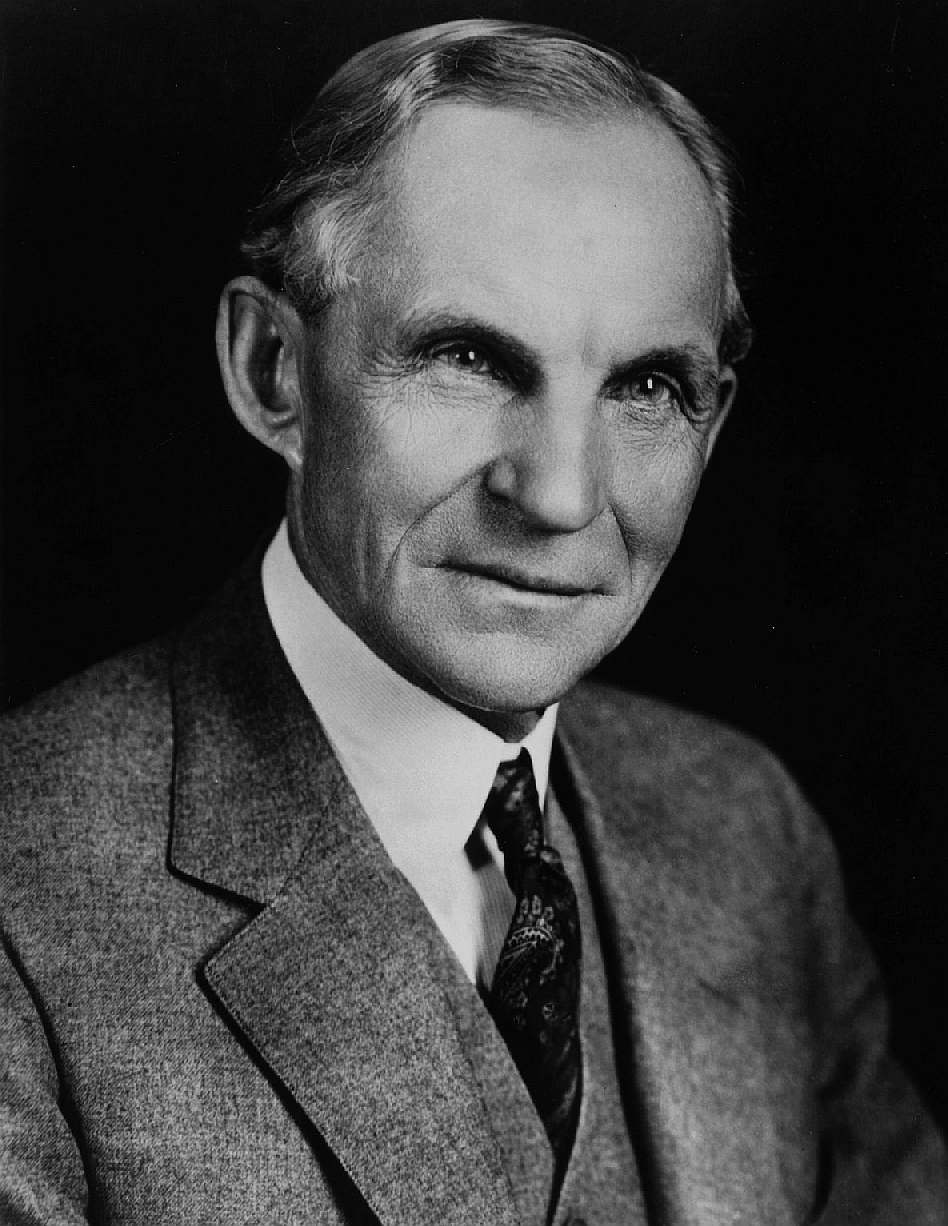

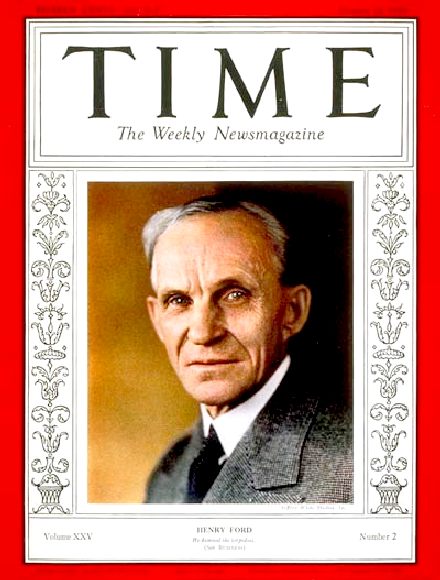

Henry

Ford - American inventor and industrialist Henry

Ford strived and failed for a great part of his life, coping with

dyslexia, but at the age of 40, he had his big breakthrough. He was an instinctive

engineer. Working for eight years as a night-shift chief engineer at Edison Illuminating Company would give him the valuable experience and inspiration to experiment on his automobile designs.

Henry Ford (July 30, 1863 – April 7, 1947) was an American industrialist, the founder of the Ford Motor Company, and the sponsor of the development of the assembly line technique of mass production.

Although Ford invented neither the automobile nor the assembly line, he developed and manufactured the first automobile that many middle class Americans could afford. In doing so, Ford converted the automobile from an expensive curiosity into a practical conveyance that would profoundly impact the landscape of the 20th Century. His introduction of the Model T automobile revolutionized transportation and American industry. As the owner of the Ford Motor Company, he became one of the richest and best-known people in the world. He is credited with "Fordism": mass production of inexpensive goods coupled with high wages for workers. Ford had a global vision, with consumerism as the key to peace. His intense commitment to systematically lowering costs resulted in many technical and business innovations, including a franchise system that put dealerships throughout most of North America and in major cities on six continents. Ford left most of his vast wealth to the Ford Foundation and arranged for his family to control the company permanently.

Ford was also widely known for his pacifism during the first years of

World War I, and for promoting

antisemitism through his newspaper The Dearborn Independent and the book The International Jew.

EDISON

ILLUMINATING COMPANY 1891

In 1891, Ford became an engineer with the Edison Illuminating Company. After his promotion to Chief Engineer in 1893, he had enough time and money to devote attention to his personal experiments on

gasoline engines. These experiments culminated in 1896 with the completion of a self-propelled vehicle which he named the Ford Quadricycle. He test-drove it on June 4. After various test drives, Ford brainstormed ways to improve the Quadricycle.

Also in 1896, Ford attended a meeting of Edison executives, where he was introduced to Thomas Edison. Edison approved of Ford's automobile experimentation. Encouraged by Edison, Ford designed and built a second vehicle, completing it in 1898. Backed by the capital of Detroit lumber baron William H. Murphy, Ford resigned from the Edison Company and founded the Detroit Automobile Company on August 5, 1899. However, the automobiles produced were of a lower quality and higher price than Ford wanted. Ultimately, the company was not successful and was dissolved in January 1901.

"Enthusiasm is the yeast that makes your hopes shine to the stars. Enthusiasm is the sparkle in your eyes. The irresistible surge of will and energy to execute your ideas."

—

Henry

Ford

With the help of C. Harold Wills, Ford designed, built, and successfully raced a 26-horsepower automobile in October 1901. With this success, Murphy and other stockholders in the Detroit Automobile Company formed the Henry Ford Company on November 30, 1901, with Ford as chief engineer. In 1902, Murphy brought in Henry M. Leland as a consultant; Ford, in response, left the company bearing his name. With Ford gone, Murphy renamed the company the Cadillac Automobile Company.

Teaming up with former racing cyclist Tom Cooper, Ford also produced the 80+ horsepower racer "999" which Barney Oldfield was to drive to victory in a race in October 1902. Ford received the backing of an old acquaintance, Alexander Y. Malcomson, a Detroit-area coal dealer. They formed a partnership, "Ford & Malcomson, Ltd." to manufacture automobiles. Ford went to work designing an inexpensive automobile, and the duo leased a factory and contracted with a machine shop owned by John and Horace E. Dodge to supply over $160,000 in parts. Sales were slow, and a crisis arose when the Dodge brothers demanded payment for their first shipment.

FORD MOTOR COMPANY

In response, Malcomson brought in another group of investors and convinced the Dodge Brothers to accept a portion of the new company. Ford & Malcomson was reincorporated as the Ford Motor Company on June 16, 1903, with $28,000 capital. The original investors included Ford and Malcomson, the Dodge brothers, Malcomson's uncle John S. Gray, Malcolmson's secretary James Couzens, and two of Malcomson's lawyers, John W. Anderson and Horace Rackham. Ford then demonstrated a newly designed car on the

ice of Lake St. Clair, driving 1 mile (1.6 km) in 39.4 seconds and setting a new land speed record at 91.3 miles per hour (146.9 kilometres per hour). Convinced by this success, the race driver Barney Oldfield, who named this new Ford model "999" in honor of the fastest locomotive of the day, took the car around the country, making the Ford brand known throughout the United States. Ford also was one of the early backers of the Indianapolis 500.

FORD

DIESEL - [LEFT] This is a modern 3.2-liter engine from the

famous American car maker. It produces 197 hp and 347 lb-ft of torque in

European specification with 90 percent of peak torque available from

1,700 to 3,500 rpm, just where it is needed for the AmphiMax

power pumps. The inline-five diesel’s torque curve is said to be

as flat as the Bonneville salt raceway. [RIGHT} It's a little known fact

that on January the 4th 1912, Henry Ford set a land speed record on ice

at 91.37 mph on the frozen surface of Michigan’s Lake St. Clair. He

was driving a four-wheel vehicle, dubbed the “999,” with a wooden

chassis and an upright steering wheel. Nice one Henry.

MODEL T

The Model T was introduced on October 1, 1908. It had the steering wheel on the left, which every other company soon copied. The entire engine and transmission were enclosed; the four cylinders were cast in a solid block; the suspension used two semi-elliptic springs. The car was very simple to drive, and easy and cheap to repair. It was so cheap at $825 in 1908 ($21,990 today) (the price fell every year) that by the 1920s, a majority of American drivers had learned to drive on the Model T.

Ford created a huge publicity machine in Detroit to ensure every newspaper carried stories and ads about the new product. Ford's network of local dealers made the car ubiquitous in almost every city in North America. As independent dealers, the franchises grew rich and publicized not just the Ford but the concept of automobiling; local motor clubs sprang up to help new drivers and to encourage exploring the countryside. Ford was always eager to sell to farmers, who looked on the vehicle as a commercial device to help their business. Sales

skyrocketed - several years posted 100% gains on the previous year. Always on the hunt for more efficiency and lower costs, in 1913 Ford introduced the moving assembly belts into his plants, which enabled an enormous increase in production. Although Ford is often credited with the idea, contemporary sources indicate that the concept and its development came from employees Clarence Avery, Peter E. Martin, Charles E. Sorensen, and C. Harold Wills.

Sales passed 250,000 in 1914. By 1916, as the price dropped to $360 for the basic touring car, sales reached

472,000. (Using the consumer price index, this price was equivalent to $7,828.08 in 2015 dollars.)

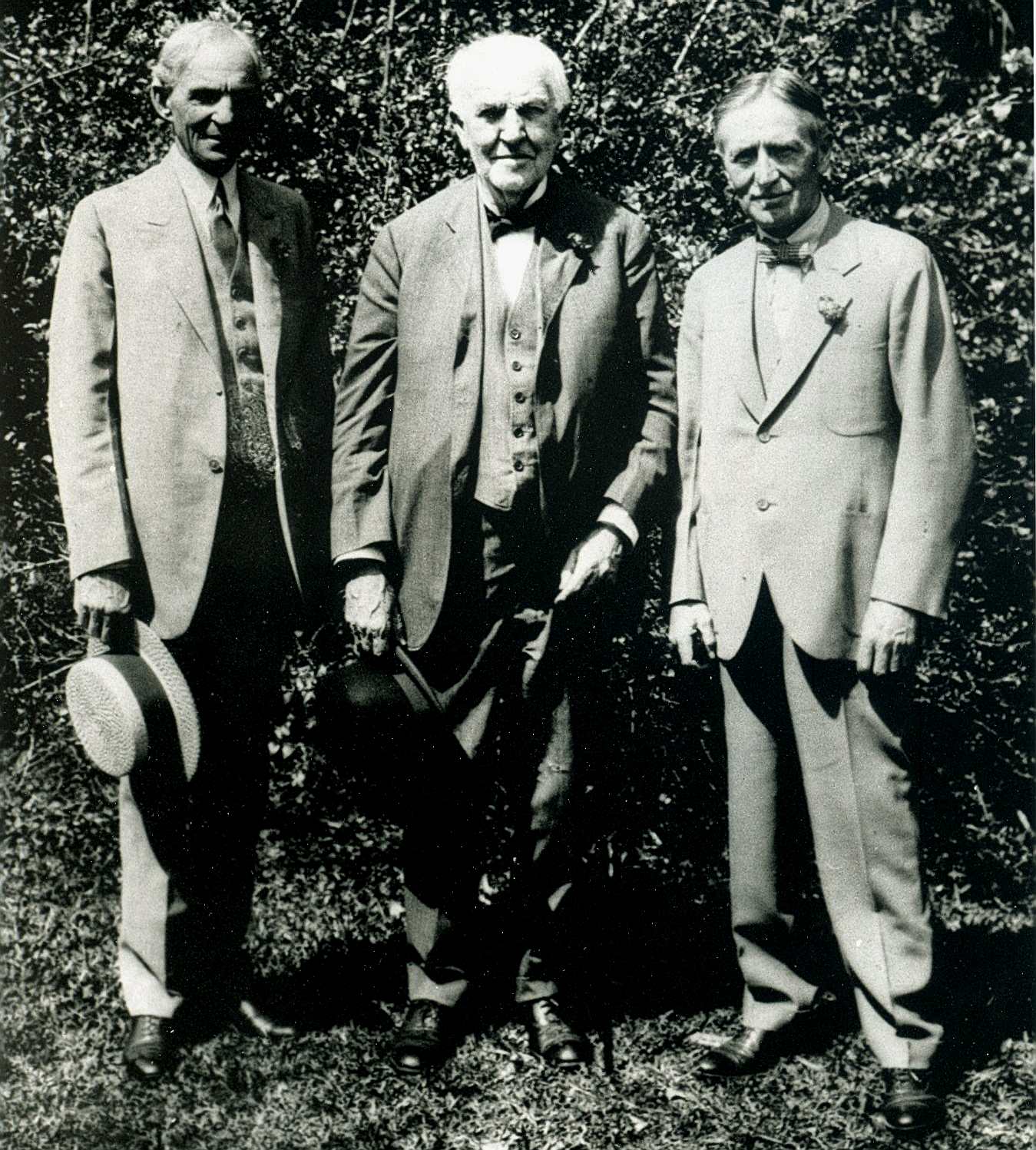

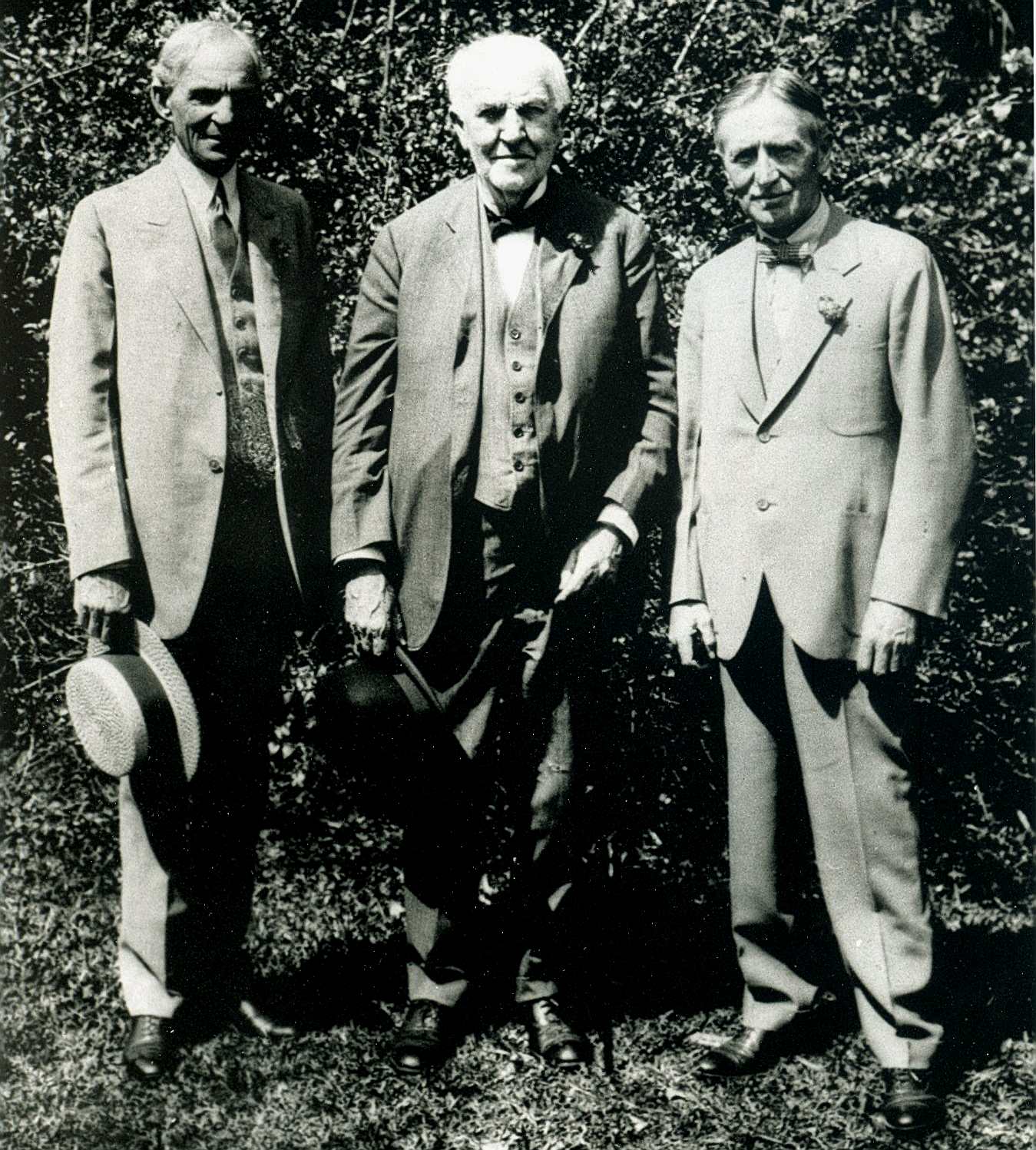

Henry

Ford, Thomas Edison and Harvey Firestone

By 1918, half of all cars in America were Model T's. All new cars were black; as Ford wrote in his autobiography,

"Any customer can have a car painted any color that he wants so long as it is

black". Until the development of the assembly line, which mandated black because of its quicker drying time, Model Ts were available in other colors, including red. The design was fervently promoted and defended by Ford, and production continued as late as 1927; the final total production was 15,007,034. This record stood for the next 45 years. This record was achieved in 19 years from the introduction of the first Model T (1908).

President Woodrow Wilson asked Ford to run as a Democrat for the

United States Senate from Michigan in 1918. Although the nation was at war, Ford ran as a peace candidate and a strong supporter of the proposed League of

Nations. Ford was defeated in a close election by the Republican candidate, Truman Newberry, a former United States Secretary of the

Navy.

Henry Ford turned the presidency of Ford Motor Company over to his son Edsel Ford in December 1918. Henry retained final decision authority and sometimes reversed the decisions of his son. Henry started another company, Henry Ford and Son, and made a show of taking himself and his best employees to the new company; the goal was to scare the remaining holdout stockholders of the Ford Motor Company to sell their stakes to him before they lost most of their value. (He was determined to have full control over strategic decisions.) The ruse worked, and Henry and Edsel purchased all remaining stock from the other investors, thus giving the family sole ownership of the company.

By the mid-1920s, sales of the Model T began to decline due to rising competition. Other auto makers offered payment plans through which consumers could buy their cars, which usually included more modern mechanical features and styling not available with the Model T. Despite urgings from Edsel, Henry refused to incorporate new features into the Model T or to form a customer credit plan.

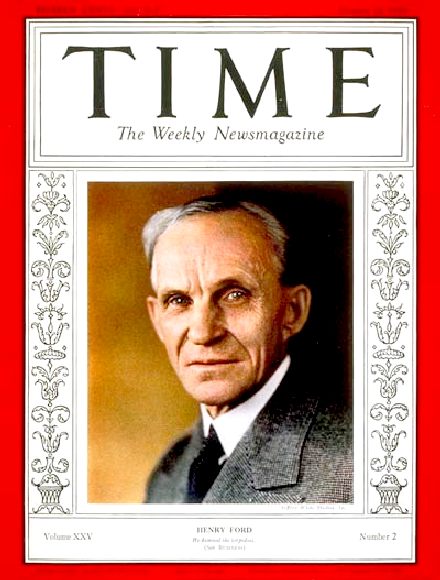

Henry

Ford was awarded this medal by Nazi Germany, the service cross of the German eagle

. Not only was he producing cars for the people, one of Adolf

Hitler's dreams, but he also campaigned against the Jews in America.

Henry's ideals were thus discriminatory in human

rights terms - rather surprising when he treated his work force so

well.

MODEL A

By 1926, flagging sales of the Model T finally convinced Henry to make a new model. He pursued the project with a great deal of technical expertise in design of the engine, chassis, and other mechanical necessities, while leaving the body design to his son. Edsel also managed to prevail over his father's initial objections in the inclusion of a sliding-shift transmission.

The result was the successful Ford Model A, introduced in December 1927 and produced through 1931, with a total output of more than 4 million. Subsequently, the Ford company adopted an annual model change system similar to that recently pioneered by its competitor General Motors (and still in use by automakers today). Not until the 1930s did Ford overcome his objection to finance companies, and the Ford-owned Universal Credit Corporation became a major car-financing operation.

Ford did not believe in accountants; he amassed one of the world's largest fortunes without ever having his company audited under his administration.

PRODUCTION

LINE Ford's greatest innovation was the production line assembly

that he pioneered. Coupled with his $dollar reward system and resting of

the workforce for two days at the weekend, Henry knew that he would get

the best out of his workers and that they would respect him for that, so

be more loyal to his company.

FIVE $ DOLLARS A DAY

Ford was a pioneer of "welfare capitalism", designed to improve the lot of his workers and especially to reduce the heavy turnover that had many departments hiring 300 men per year to fill 100 slots. Efficiency meant hiring and keeping the best workers.

Ford astonished the world in 1914 by offering a $5 per day wage ($120 today), which more than doubled the rate of most of his workers. A Cleveland, Ohio, newspaper editorialized that the announcement "shot like a blinding rocket through the dark clouds of the present industrial depression." The move proved extremely profitable; instead of constant turnover of employees, the best mechanics in Detroit flocked to Ford, bringing their human capital and expertise, raising productivity, and lowering training costs. Ford announced his $5-per-day program on January 5, 1914, raising the minimum daily pay from $2.34 to $5 for qualifying male workers.

THE

MODEL T - Henry

sits in one of his black automobiles. The Ford Model T (colloquially known as the Tin Lizzie,

T Model Ford, Model T, T, Leaping Lena, or flivver) is an automobile that was produced by Ford Motor Company from October 1, 1908, to May 26, 1927. It is generally regarded as the first affordable automobile, the car that opened travel to the common middle-class American; some of this was because of Ford's efficient fabrication, including assembly line production instead of individual hand crafting.

The Ford Model T was named the most influential car of the 20th century in the 1999 Car of the Century competition, ahead of the BMC Mini, Citroën DS, and

Volkswagen Type 1. Ford's Model T was not only successful because it provided inexpensive transportation on a massive scale, but also because the car signified innovation for the rising middle class and became a powerful symbol of America's age of modernization. With 16.5 million sold it stands eighth on the top ten list of most sold cars of all time as of 2012.

Although automobiles had already existed for decades, they were still mostly scarce and expensive at the Model T's introduction in 1908. Positioned as reliable, easily maintained mass market transportation, it was a runaway success. In a matter of days after the release, 15,000 orders were placed. The first production Model T was produced on August 12, 1908 and left the factory on September 27, 1908, at the Ford Piquette Avenue Plant in Detroit, Michigan. On May 26, 1927, Henry Ford watched the 15 millionth Model T Ford roll off the assembly line at his factory in Highland Park, Michigan.

There were several cars produced or prototyped by Henry Ford from the founding of the company in 1903 until the Model T was introduced. Although he started with the Model A, there were not 19 production models (A through T); some were only prototypes. The production model immediately before the Model T was the Model S, an upgraded version of the company's largest success to that point, the Model N. The follow-up was the Ford Model A (rather than any Model U). The company publicity said this was because the new car was such a departure from the old that Henry wanted to start all over again with the letter A.

The Model T was Ford's first automobile mass-produced on moving assembly lines with completely interchangeable parts, marketed to the middle class. Henry Ford said of the vehicle:

"I will build a car for the great multitude. It will be large enough for the family, but small enough for the individual to run and care for. It will be constructed of the best materials, by the best men to be hired, after the simplest designs that modern engineering can devise. But it will be so low in price that no man making a good salary will be unable to own one – and enjoy with his family the blessing of hours of pleasure in God's great open spaces."

Although credit for the development of the assembly line belongs to Ransom E. Olds with the first mass-produced automobile, the Oldsmobile Curved Dash, beginning in 1901, the tremendous advancements in the efficiency of the system over the life of the Model T can be credited almost entirely to the vision of Ford and his engineers.

Detroit was already a high-wage city, but competitors were forced to raise wages or lose their best workers. Ford's policy proved, however, that paying people more would enable Ford workers to afford the cars they were producing and be good for the local economy. He viewed the increased wages as profit-sharing linked with rewarding those who were most productive and of good character. It may have been Couzens who convinced Ford to adopt the $5-day.

The profit-sharing was offered to employees who had worked at the company for six months or more, and, importantly, conducted their lives in a manner of which Ford's "Social Department" approved. They frowned on heavy drinking, gambling, and (what today are called) deadbeat dads. The Social Department used 50 investigators, plus support staff, to maintain employee standards; a large percentage of workers were able to qualify for this "profit-sharing."

Ford's incursion into his employees' private lives was highly controversial, and he soon backed off from the most intrusive aspects. By the time he wrote his 1922 memoir, he spoke of the Social Department and of the private conditions for profit-sharing in the past tense, and admitted that "paternalism has no place in industry. Welfare work that consists in prying into employees' private concerns is out of date. Men need counsel and men need help, often special help; and all this ought to be rendered for decency's sake. But the broad workable plan of investment and participation will do more to solidify industry and strengthen organization than will any social work on the outside. Without changing the principle we have changed the method of payment."

THE FIVE DAY WORKING WEEK

In addition to raising the wages of his workers, Ford also introduced a new, reduced workweek in 1926. The decision was made in 1922, when Ford and Crowther described it as six 8-hour days, giving a 48-hour week, but in 1926 it was announced as five 8-hour days, giving a 40-hour week.(Apparently the program started with Saturday being a workday and sometime later it was changed to a day off.) On May 1, 1926, the Ford Motor Company's factory workers switched to a five-day 40-hour workweek, with the company's office workers making the transition the following August.

Ford had made the decision to boost productivity, as workers were expected to put more effort into their work in exchange for more leisure time, and because he believed decent leisure time was good for business, since workers would actually have more time to purchase and consume more goods. However, altruistic concerns also played a role, with Ford explaining "It is high time to rid ourselves of the notion that leisure for workmen is either ‘lost time’ or a class privilege."

LINKS

& REFERENCE

https://en.wikipedia.org/wiki/Henry_Ford

INVENTORS

A - Z

SEAVAX

- is a battery electric ASV (Autonomous Solar Vessel), a trimaran robot that runs on solar power =

energy from nature. A fleet of such vessels could be the basis of

an international ocean plastic cleanup campaign in the hope of protecting

marine mammals and improving the health of wild fish stocks.

|