|

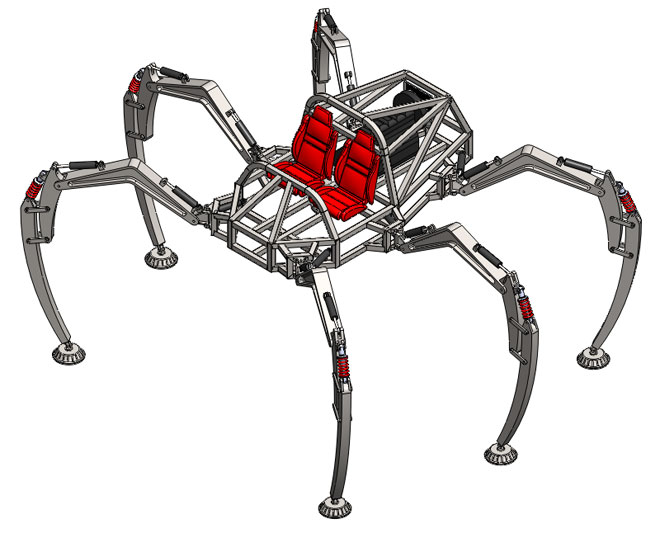

STOMPY GIANT ROBOT HEXAPOD

|

|

|

|

Stompy hydraluic leg parts before assembly and proud Asylum team members

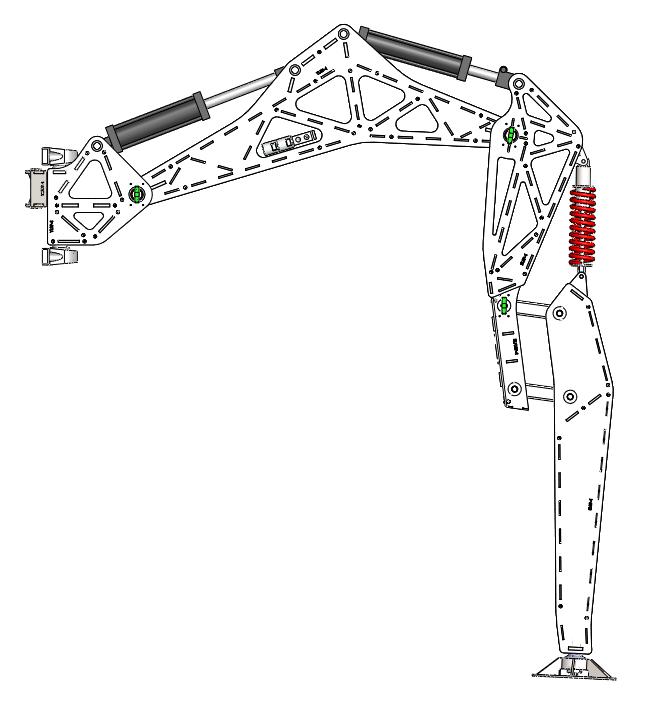

The circle on the left is Stompy's footpad. Because area scales exponentially with diameter, that size foot produces a pressure on the ground almost identical to that of a human foot (even though Stompy weighs 4,000 pounds...), meaning we can walk anywhere a human can walk without damaging the terrain. Next up is the compliant link - that's the part that will move up and down with respect to the knee link, by means of the giant shock absorber you see on the table. This is meant to absorb the tremendous load of suddenly hitting the ground. The knee link is connected to the thigh link (the bridge looking thing), and the thigh link is connected to the giant yaw link at the right end of the table.

KICKSTARTER PROJECT

The

crew are creating “an open-source, 18ft wide, 4,000 pound, 6-legged hydraulic robot that you can ride.” Project Hexapod is a robotics class turned Kickstarter project that hit its initial funding goal of $65,000

with ease - confirming the level of interest.

The robot isn't just being built just for fun - it has many practical purposes. With 6 force-sensitive legs and a ground clearance of 6 feet, the robot will be able to walk over broken terrain that varies from mountainous areas, to rubble piles, to water up to 7 or 8 feet deep - everywhere existing ground vehicles can't go. Not only that, but while navigating such terrain, Stompy could carry 1,000 pounds at 2-3 mph, and up to 4,000 pounds at 1 mph. This is important because in disaster areas like Haiti's Port Au Prince, it's taken more than three years to clear the rubble out of some areas - meaning that throughout that entire time, people have had to be rescued or resupplied by helicopter, because no ground vehicle could reach them. Stompy (and the technology it represents) could easily reach people who can't be reached by any other means in a natural disaster.

Artisan's Asylum Workshop: Stompy full team group photo

They’ll upgrade

the hydraulic powerplant to allow for a higher ground speed. They’ll also add sensors that will allow for some amount of autonomy, for future robot development.

A walking Hexapod is nice to travel in, but one that could hit 60mph on the

freeway - is it possible. The Mantis

built by Matt Denton manages 1mph using a 2 litre IC

engine. That being the case, the Stompy crew face a serious challenge. The

quickest robot hexapod design to date is the Insectronics

robot inspired by an Australian

bulldog ant, which uses a compact hydraulic leg actuator based on four close

coupled cylinders on a gimbal joint to achieve 20mph - the limitation being

the hydraulic pump capacity.

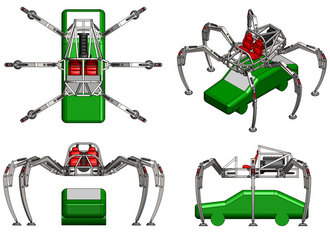

A collection of CAD drawings showing the scale of Stompy in concept

CONCEPT

Their first course set out to build 300-lb autonomous "vending machine robots." That class is winding down, so they're starting a new project: a 2500+ lb. ridable hexapod "spider" robot named Stompy. The robot will feature a propane engine generating 135 HP to hydraulically power six legs, and it will likely cost around

$25k-$30k to build (versus $250k that would typically be involved in such an effort). The guys teaching the class are professional roboticsts, having worked at Boston Dynamics, Barrett Technology, and DEKA. So this is a serious endeavor! They're following the same design methodologies that their (current and former) employers use to produce classics such as BigDog, AlphaDog, and PETMAN. They're using the proceeds from the class to fund early development (a one leg cart), followed by a KickStarter project to fund the remainder of the robot (forthcoming announcement). It's a clever way to fund a large robot hardware platform. Conceivably, they could use the resulting robot to generate revenue to for the startup (rentals for promotional events, parades, or wedding processions!) and to bootstrap other robots. Read on for details supplied by Artisan's CEO, Gui

Cavalcanti.

OTHER ROBOT PROJECTS

This subject has received a lot of attention from other engineers:-

A-Pod is an ant inspired hexapod robot with a 2 DOF abdomen (tail), a 3 DOF head with large mandibles. 6 legs with 3 DOF each. Total 25 servos. This video demonstrates body movement and mandible control.

The designer still has to make some mechanical improvements to the legs

(explaining the small amount of walking). The robot is remotely controlled with a custom 2,4 GHz RC transmitter. The Basic Atom Pro 28

is/are used as the main micro-controller(s).

FireAnt is based on Zenta's A-POD and made from all aluminum anodized brackets. The kit includes the new digital HV220 robotic servos with position and force feedback. This gives FireAnt life like movement and the ability to sense its environment. It can sense the force the pincher's are applying with no additional sensors. It can also feel when a leg is touching something in both down and forward directions for autonomous terrain adaptation.

http://www.orionrobotics.com/FireAnt-Hexapod-Robot_p_248.html

Stompy's leg parts compared to a human - and the IC power plant

LINKS

http://www.sussex.ac.uk/profiles/dr_paul_graham http://www.bbc.co.uk/news/ants http://fallout.wikia.com/wiki/File:Giant_ant http://killallmonsters.com/ants http://themediumandthemayhem.net/2011/08/26/ferroluar/ http://fallout.wikia.com/wiki/Giant_ant http://projecthexapod.com/blog/ http://www.kickstarter.com/projects/projecthexapod/stompy-the-giant-rideable-walking-robot https://www.facebook.com/ProjectHexapod http://solidsmack.com/3d-cad-technology/get-on-board-the-giant-six-legged-robot-you-can-ride/ http://www.wired.com/autopia/2012/05/stompy-project-hexapod/ http://boingboing.net/2012/05/02/stompy-is-coming.html http://hackaday.com/2012/05/03/meet-stompy-your-new-robotic-overlord/ http://www.dvice.com/archives/2012/05/meet-stompy-a-2.php http://www.hizook.com/artisans-asylum-hackerspace-startup-building-2500-lb-rideable-hexapod-robot http://www.bostonglobe.com/business/2012/05/05/catching-new-wave-courses http://www.engadget.com/2012/06/14/project-hexapod-eyes-on/ http://projecthexapod.com/blog/swag-design-contest/

A project with bite. These robot jaws (when made of steel) shut with a pressure of up to 2 tons and in less than a quarter of a second.

Lurking beneath the Antarctic ice is a discovery that scientist will die for.

BIPEDS | CYBEE | HEXAPODS | MANTIS | OCTOPODS QUADRUPEDS | ROBOBEE | ROBOT ANT | SPIDERBOT | STOMPY | TRIPODS

....... The World in Your Hands

|

||

|

This website is copyright © 1991- 2013 Electrick Publications. All rights reserved. The bird logo and names Solar Navigator and Blueplanet Ecostar are trademarks ™. The Blueplanet vehicle configuration is registered ®. All other trademarks hereby acknowledged and please note that this project should not be confused with the Australian: 'World Solar Challenge'™which is a superb road vehicle endurance race from Darwin to Adelaide. Max Energy Limited is an educational charity working hard to promote world peace.

|

||