|

KORT NOZZLES

|

|||||||||||||||||||||

|

HOME | BIOLOGY | FILMS | GEOGRAPHY | HISTORY | INDEX | INVESTORS | MUSIC | NEWS | SOLAR BOATS | SPORT |

|||||||||||||||||||||

|

The Kort nozzle is a shrouded, ducted propeller assembly for marine propulsion. The hydrodynamic design of the shroud, which is shaped like a foil, offers advantages for certain conditions over bare propellers.

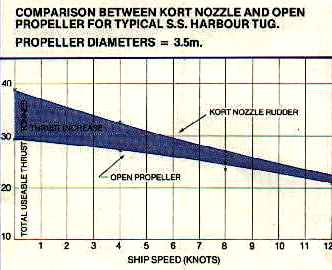

Kort nozzles or ducted propellers can be significantly more efficient than un-ducted propellers at low speeds, producing greater thrust in a smaller package. For the Bollard Pull it may produce as much as 50% greater thrust per unit power than a propeller without a duct. Tugboats are the most common application for Kort nozzles as highly loaded propellers on slow moving vessels benefit the most.

The additional shrouding adds drag, however, and Kort nozzles lose their advantage over propellers at about ten knots (18,52 km/h), although with the latest advances in design the maximum working speed may be increased to 15 knots.

Kort nozzles may be fixed, with directional control coming from a rudder set in the water flow, or pivoting, where their flow controls the vessel's steering

Ludwig Kort patent application drawings 1938

HISTORY

Luisa Stipa and later Ludwig Kort (1934) demonstrated that an increase in propulsive efficiency could be achieved by surrounding the propeller with a foil shaped shroud in the case of heavily loaded propellers. A "Kort Nozzle" is referred to as an accelerating nozzle and is generally a MARIN 19a profile or a MARIN 37 profile.

The idea of putting a shroud around a propeller is very old but it was only in 1934 that Stipa and Kort showed that a practical propeller of this design was possible. Kort designed a whole series of ducted propellers which proved very valuable when used in ships like tugs, pushboats, supply ships, trawlers etc. For this reason, his designs became known as Kort Nozzles.

His breakthrough was to shape the shroud around the propeller like an aerofoil rather than a simple ring. If the high-pressure side of the aerofoil faces outwards (so the top is like an aircraft wing right way up), the duct is of the decelerating type. If the low pressure side is outwards (so the top is like an aircraft wing upside down) the duct is accelerating. An accelerating duct produces positive thrust and increases the efficiency of heavily-loaded props (a heavily-loaded prop is one where the power being put through it is close to the maximum absorbable for that prop design). A decelerating duct produces a negative thrust and is valuable for reducing cavitation. A decelerating duct is a major contributor to noise reduction which is why it is getting more popular with modern warship designs.

Kort nozzle boat construction

The major problem with ducted props is flow separation. This causes the drag of the whole system to increase sharply, efficiency drops and the propeller tries to work in a highly irregular flow. This is bad. A mass of work has been done on the standards for ducted propellers and a number of "optimum" units designed. These are referred to by numbers, the simplest member being Nozzle No.19A. Nozzle No.22 for example, has a longer shroud in proportion to the prop diameter and is more efficient but gives poor backing characteristics. If a commercial designer wants to use Kort Nozzles, he'll decide on the characteristics he wants then selects the appropriate nozzle.

In summary, ducted propellers are well suited for situations where the propeller has to accommodate heavy loads. However, such prop designs cannot work safely without flanking rudders for the prop race since ducted props give virtually no backing control. In passing, flanking rudders are a pretty good idea since rudder control on ships doesn't usually work below around 10 knots and under this speed ships have to steer using their engines. While no great problem with twin and quad screw configurations, this is impossible with single screw ships. In this case, flanking rudders can offer some element of control at low speeds. In passing, German S-boats used a rudder trick (called the Lurssen Effekt) to push their sterns down and thus get slightly better efficiency for their props.

A pump jet is a developed Kort Nozzle in which the shroud is extended and fixed guidevanes are installed fore and aft of the propeller. The duct diameter increases from the entrance of the duct to the propeller so that the velocity of the water falls and the pressure increases. This means that the prop diameter is larger and the thrust loading drops. A lot of the design art in this area is classified and the only treatment available in open source comes from Henderson in 1963.

Kort nozzle performance comparison graph

APPLICATIONS

The advantages of Kort Nozzles are well known for towing vessels such as tugs and fishing boats, however significant improvements in performance can be achieved on vessels such as coasters, inland waterways craft and bulk carriers using designs optimised for each vessel type.Kort has enjoyed remarkable success since the first Kort Nozzles were fitted in 1935!

The thrust increase available to vessels working at low speed of advance is now common knowledge, although designs must be optimised to suit every vessel operation, whether a 500mm thruster for an ROV or a bulk carrier with 5300mm Kort Steering Nozzle.

Tugs, trawlers, dredgers and offshore supply vessels are typical of the application where a Kort nozzle can provide up to 25-30% improvement in thrust at low speed. This allows a reduction in installed power for a given performance.

A fishing vessel, for example, can work larger gear in deeper waters or maintain speed in bad weather as proven by the many thousands of of trawlers fitted with Kort Nozzles worldwide. Kort Steering Nozzles worldwide provide excellent manoeuvrability, giving a positive response to small angles of helm when going ahead or astern.

The key to vessel performance is the correct design of propeller and Kort Nozzle in combination and Kort has the expertise and experience to provide this for both fixed or controllable pitch propeller systems.

Kort nozzle part submerged during launch

TESTS

Two recent conversions prove that the increased trawling thrust from a Kort Nozzle system can reduce fuel consumption.

A Kort Nozzle system gives 20-25% increase in thrust when towing. A vessel with 800 bhp and 2000mm open propeller achieves 8.6 tonnes. 8.6 tonnes can be achieved using 640 bhp with a Kort Nozzle system. A 20% reduction in engine power for the same towing thrust!

Comparison @ 3 Knots Towing

BHP 170 190 210 230 250 270 285 Kort Nozzle(t) 2.68 2.90 3.10 3.30 3.55 3.75 3.95 max. Open Screw(t) 2.30 2.48 2.65 2.83 3.02 3.20 max.

The

Importance of Propeller diameter Propeller Diameter(mm) 1300 1600 1900 2200 2500 Shaft RPM 400 280 210 160 130 Kort Nozzle 3.92 4.45 5.00 5.50 6.00

A significant improvement by increasing propeller diameter using the same 295bhp engine!

In fact the Kort Nozzle system provides more thrust with either fixed pitch or CP propellers has been proved beyond doubt. Whether a 10m vesel with 100 hp or a 40m vessel with 2000 hp the benefits of the Kort Nozzle are the same.

Phelix Drive rear Phelix Drive front

Phelix Electric Outboard motor drive Fishing Boat Project

RICE KORT NOZZLE

Rice Thrust Nozzles for Tugs

The Rice Thrust Nozzle* is replacing the Kort Nozzle type 37 around the world because its hydrodynamic shape produces less drag and better performance.

Rice

Thrust Nozzle Profile

Designed

for Tugs, the unique shape works to maximise both forward and reverse

thrust.

Twin Rice thrust nozzle installation

The

Rice Thrust nozzle is designed to obtain maximum bollard pull.

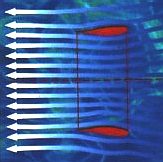

How a Marine Nozzle Works

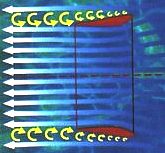

To obtain the most thrust, a propeller must move as much water as possible in a given time. A nozzle will assist the propeller in doing this, especially when a high thrust is needed at a low ship speed. As we already know, as the propeller blades rotate in the water, they generate high-pressure areas behind the each blade and low pressure areas in front, and it is this pressure differential that provides the force to drive the vessel. However, losses occur at the tip of each blade as water escapes from the high pressure side of the blade to the low pressure side, resulting in little benefit in terms of pushing the vessel forward. The presence of a close fitting duct around the propeller reduces these loses by restricting water flow to the propeller tips.

The cross sectional area at the entrance of the nozzle is greater than at the trailing throat. Since the water density is constant, the water must accelerate from one to the other. Hence the water is already moving faster as it reaches the propeller than it would on a conventional open propeller. Therefore, more water is moved and more thrust created for the same input power and torque.

However, there are efficiency gains to be made even when it comes to the nozzle design. Some designs will drag as the speed of the advance increases. With the Kort nozzle design, this drag becomes more significant at higher speeds and can eventually reduce the overall thrust gain to zero. The coefficient of drag is over 17 times less with the Rice speed nozzle than the Kort 19A design.

The section of a Rice-Speed Nozzle was developed from air wing sections displaying highest lift/lowest drag properties. When nozzle sections of Kort 19-A and Rice-Speed are compared in Figure 2 below, the drag coefficient of a Rice-Speed Nozzle is 17 times lower than Kort 19-A type.

The section of a Rice-Speed Nozzle was developed from air wing sections displaying highest lift/lowest drag properties. When nozzle sections of Kort 19-A and Rice-Speed are compared in Figure 2 below, the drag coefficient of a Rice-Speed Nozzle is 17 times lower than Kort 19-A type.

Due to the design (Figure 3), the propellerís working area in the centre of nozzle, is approximately 40% smaller than the area of the nozzle entrance. This results in an increase of water speed and a decrease of internal pressure in relation with external pressure - which remains more or less constant.

Kort Nozzle .17 cd (fig3) Rice Nozzle .01 cd (fig4)

Because of this pressure difference, a force P (Figure 4) is created on the external surface of the nozzle that is always perpendicular to this surface.

Beautiful Rice thrust nozzle in stainless steel

Marine Nozzle Tests

Trawlers

To demonstrate the difference in design efficiencies, tests were conducted using (3) 72 foot trawlers of 375 Hp @ 1800rpm with 6:1 reduction gear each performing the same work. One was fitted with an open propeller, one with a Kort nozzle and a Kaplan propeller, and the third with a Rice Speed Nozzle and Rice Skewed Kaplan.

Test results :-

Open Prop 66" x 44" Bollard Pull: 4708 kg Max Speed: 9.3 knots. Fuel: 1512 lts/day Kort Nozzle 61" x 56" Bollard Pull: 6646 kg Max Speed: 9.0 knots. Fuel: 1264.5 l/day Rice Nozzle 61.25x 59 Bollard Pull: 7182 kg Max Speed:10.0 knots. Fuel: 1174.5 l/day

These real test results show significant gains:-

Tugs

In further trials between two sister tug vessels, the Rice Thrust Nozzle System (Rice TN) again outperformed the older Kort 37 nozzle. (see Table below)

(Results Certified by Bureau Veritas)

The Rice Thrust Nozzle is based on the Rice Speed Nozzle profile and was especially developed for tug work to maximize efficiency with both forward and astern thrust.

The Patented Rice Nozzle has less drag than the Kort nozzle due to its hydrodynamic design. This means previously lost engine power of about 10% can now be used as extra pitch which increases free running speed approx 10% and trawling thrust by 6% approx.

Rice had made 4800 Kort nozzles (originally designed in 1935) before developing the superior Rice Speed nozzle. Well over 2500 Rice Speed nozzles are now in use world wide since introduction in 1985. The Kort nozzle's biggest draw back is the high drag coefficient which is successfully addressed with the more efficient Rice Speed Nozzle.

A large Rice thrust nozzle with makers standing inside

PROPULSOR

A propulsor is a mechanical device that gives propulsion.

The word is commonly used in the marine vernacular, and implies a mechanical assembly that is more complicated than a propeller. The Kort nozzle and Pump-jet are examples.

A propulsor, as can be seen in the accompanying picture has a shroud, which cuts down on blade-tip cavitation and radiated noise. It also has a rotor element and a stator. The stator concentrates the thrust in axial direction and reduces energy wasted in the tangantial flow (therefore eliminating torque on the hull). The number of blades in the rotor & stator will typically be odd-numbered, and different prime numbers to avoid standing waves. The blades in the rotor or the stator may be angled to further reduce noise. The physical design and layout is very much similar to a single stage Axial-flow compressor.

Propulsor MK 50 ducted propellor on a torpedo

BOW THRUSTERS

A bowthruster is a tunnel installed horizontally in the bow area of a ship. A propeller inside this tube is able to produce thrust into each direction pushing the bow to the respective side. On larger tugs such as offshore supply tugs, bow and stern-thruster units are installed enabling the tugs to maintain dynamic positioning also under severe weather conditions.

Bow thrusters are not Kort Nozzles although shrouded, they do not have the hydrodynamically shaped shroud to increase thrust, simply because they are mounted in a through hull tube.

CONTACTS, LINKS and REFERENCE

Kort Propulsion Bank Chambers, 70 Pier Road, Erith, Kent, DA8 1TA, United

Kingdom

Rice Propellors Ave. Rios Espinozza #88 Col. Benito Juarez Maxatlan, Sinaloa, Mexico Email: rice@ricepropulsion.com.mx Tel: 00699 983 29 44

Kort Nozzle thrusters used on Seabotix remote camera equipment

Healthier alternative tastes for adventure capitalists

Solar Red | Solar Cola | Solar Crush | Solar Citrus | Solar Spice

|

|||||||||||||||||||||

|

This

website

is Copyright © 1999 & 2007 Electrick Publications.

The bird The name '1824' is a trade mark of Solar Cola Ltd. All rights reserved. Max Energy Limited is an educational charity. |

|||||||||||||||||||||

|

AUTOMOTIVE | BLUEBIRD | ELECTRIC CARS | ELECTRIC CYCLES | SOLAR CARS |