|

-

This

was the costing for an application that was never filed, simply because

the project had no development partners and we were only notified of the

opportunity a month before the deadline.

-

-

We

have published the gist of the application to show the value returns for

potential investors - and equally importantly, to help academics

considering their own projects what might be achieved on a low budget.

-

-

For

2014, we now have Formula

E as the vehicle to drive electric car development. To this end, a

development of the LSR battery cartridge energy transfer system, is

suitable for incorporation in circuit road racers - offering pit stop

refueling in 10-15 seconds. Free developer licenses are available for

competitors. The system works equally well with batteries

and fuel cells.

-

-

-

-

Number:

29/G/ENT/CIP/12/C/N05S00 - Promotion of electric vehicle

technologies

GRANT

PROGRAMME 2012

Construction from scratch of an electric car designed for competition.

LOT

1 COSTS: ‘BLUEPLANET ECOSTAR’

| Steels |

. |

1,500 |

| Alloys |

. |

1,000 |

| Composites |

. |

1,500 |

| Paints |

. |

500 |

| Wheels/tires |

2

sets |

4,800 |

| Braking

& chutes |

. |

1,200 |

| Glass |

. |

300 |

| Suspension |

. |

2,000 |

| Safety

equipment |

. |

1,000 |

| Transmission |

. |

20,000 |

| Motors |

. |

48,000 |

| Electronics |

. |

12,000 |

| Battery

cartridges |

x

3 |

120,000 |

| Battery

loading mechanism |

. |

6,000 |

| Solar

charging arrays |

. |

55,000 |

| Welding

and other tool hire |

. |

3,000 |

| Fastenings |

. |

1,500 |

| Display

trailer |

. |

8,000 |

| Labour:

design |

2

months |

16,000 |

| Labour:

build |

4

months |

16,000 |

| Labour:

electronics design |

. |

3,000 |

| Labour:

web build |

. |

2,000 |

| Premises

rent |

6

months |

7,200 |

| Office

equipment |

. |

1,000 |

| Intellectual

property: patents |

. |

5,000 |

| Intellectual

property: trademarks |

. |

5,000 |

| Public

relations |

. |

4,000 |

|

|

|

|

|

|

|

Sub

Total |

£

346,500 |

|

|

|

| Contingency |

@

20% |

£

69,300 |

|

|

|

| . |

Grand

Total |

£

415,200 |

|

|

|

CONSTRUCTION

TIMETABLE

(1)

Scheduled start-up date for the action: 15th July 2012

(2)

The duration of the construction is 4 months.

Project:

Blueplanet Ecostar

An

electric land speed record car that refuels itself by changing battery packs

between each run - charged by solar power.

Intelligent

Battery Support System

Contact us:

Contact us:  or phone UK:

or phone UK:

+44

(0) 1323 831727

+44

(0) 7842 607865

Intelligent

Battery Support System

Intelligent

Battery Support System

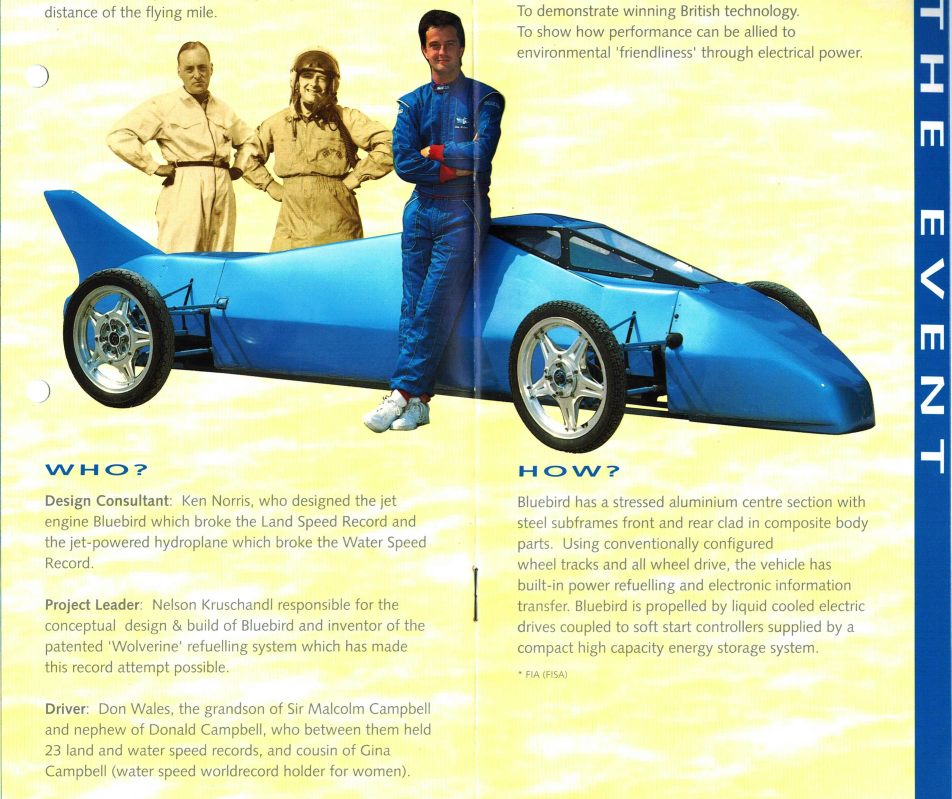

THE

BLUE BIRDS OF HAPPINESS

Enterprise

and Industry

ENERGY

GENERATING-DISTRIBUTION UTILITIES

The

historic first car ever to be fitted with the patent

"self-load" cartridge exchange

energy transfer system, now under development for the FIA

Formula E racing series.

RAPID

BATTERY INTERCHANGE (RBI) An EV with RBI capability

incurs different capitalization and operating costs to an EV with a permanent battery installation.

Analysis is based upon combinations of four vehicle mission scenarios, three vehicle types, and four usage patterns.

Lead-acid battery technology is assumed in all cases as a base line for slow and fast charge batteries, and for RBI

battery modules.

The analysis attempts to reduce to an equivalent annual cost for the vehicle(s), support equipment,

electric power costs, replacement batteries, and periodic service. All vehicles and support equipment are assigned a useful

life or fifteen years, with zero salvage value.

It is

assumed that each complete slow-charge cycle to an 80% depth of charge consumes 0.2% of the life of the

battery. A fast charge cycle to a 40% charge depth consumes 1.0% of the battery life. Batteries charged by

RBI exchange equipment are slow-charged. Power costs are incurred at either off-peak rates of $0.06 per

kWh, or $0.12 per kWh for peak power (Schedule E-19 metered time-of-use service). Fast charging is assumed

to always occur during peak hours, while slow charging

and RBI module charging is assumed to occur at night, using off-peak power. Fast chargers are assumed to

have the capability of also slow-charging a battery.

Vehicular battery interchange methods have been used for over 100 years to overcome the range and charging

time limitations of EVs. Successful implementation is typically dependent upon significant infrastructure. In situations

in which necessary infrastructure is available and range demands are high, rapid battery interchange appears to

be an economical alternative to high-rate in-vehicle battery charging.

Survey results suggest that the majority of vehicle, equipment and battery manufacturers view the concept

favorably but with skepticism. Near-term feasibility is greatest for applications in which external (not owned by

the vehicle operator) infrastructure components are not required. Only fleet applications, with vehicles serviced

from a central location meet this criteria. Among fleet applications, transit buses have been and will continue

to be the favored deployment, since they operate on a fixed route with well-defined energy requirements and

periodic visits to a common location.

A

universal energy cartridge for sustainable future transport RBI SAFETY CONCERNS PERTINENT TO THE

VEHICLE Safety issues related to electric vehicles are significant,

but battery interchange capability does not appear to add significantly to the risk of operation compared with

conventional EVs.

Accidental release of the battery module in the event of a collision. If the battery can be exchanged quickly, it is

likely to be less securely mounted than a permanent battery installation. Accidental release of a battery

module weighing 400 to 500 kg could increase the level of damage and hazard in a collision, especially to the

other vehicle.

Battery protection from the elements, and integrity in the event of collision or rollover is also a greater concern

with an RBI vehicle, since the battery would probably be more exposed than in a fixed battery installation.

Ventilation of released gases would probably be a reduced concern with RBI, but accumulation of road

debris, mud, water and snow pose an additional problem, especially in the area of the electrical contacts.

Rain or slush laden with road salt is an effective conductor, capable of shorting and/or

degrading battery and instrumentation contacts.

Electrical connectors that must engage automatically and quickly in an RBI vehicle are likely to be more

susceptible to poor contact or accidental short due to misalignment or mishandling. The contactor system

must be completely “idiot-proof,” capable of withstanding backward insertion of the battery module, poor vehicle

alignment, and possibly excessive vehicle speed upon docking with the battery exchange equipment.

CONCLUSIONS Where

fast charging is used, not only is the battery degraded more quickly, but the

electricity consumed is charged at a higher rate. On this basis and as EVs

become popular once again, RBI is a must. Not only that, RBI allows an

operator to upgrade battery or fuel cell technology without modification to

his vehicles. Extracted

from a study by: C. Arthur MacCarley

California Polytechnic State University, San Luis Obispo,

California, USA

|